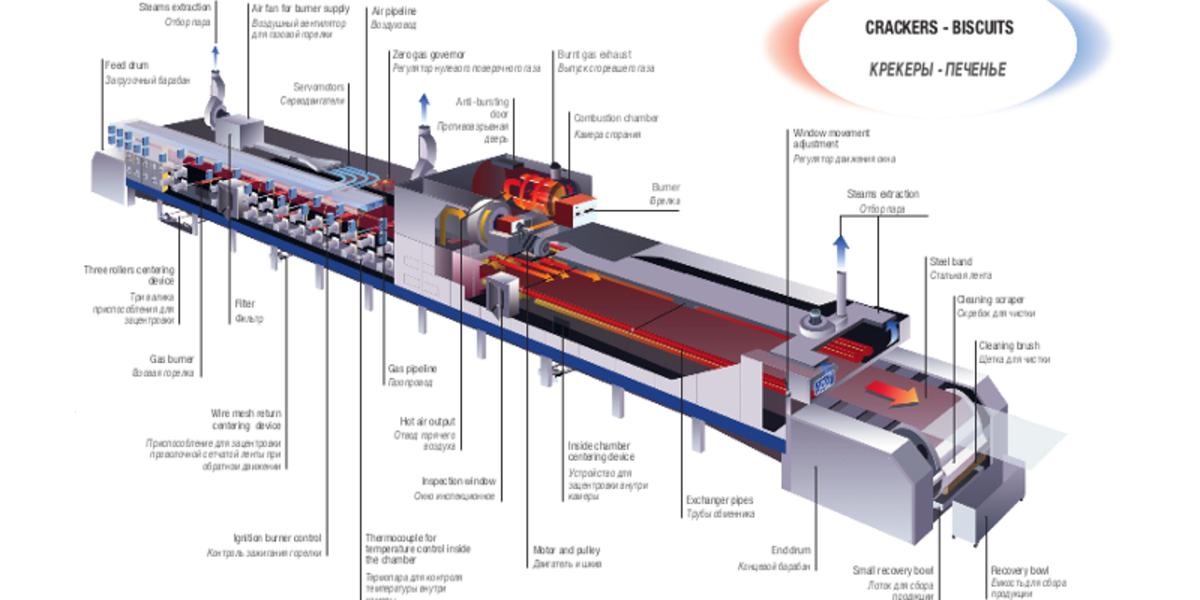

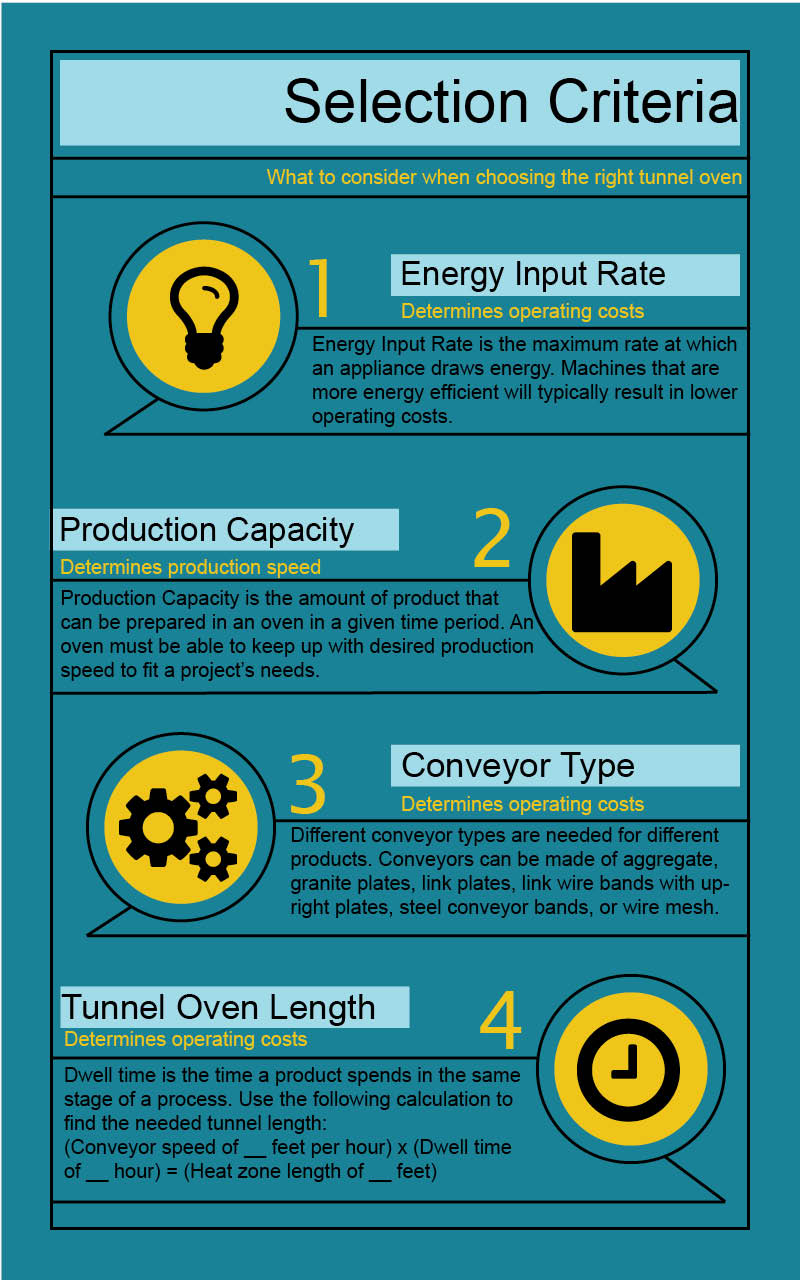

Commercial bakeries use either the tunnel oven consisting of a metal belt passing through a connected series of baking chambers open only at the ends or the tray oven with a rigid baking platform carried on chain belts.

What does a tunnel oven do.

Other types include the peel oven having a fixed hearth of stone.

Most modern commercial bakeries use either the tunnel.

A tunnel oven is continuous rather than using a batch process.

The output of all bread making systems batch or continuous is usually keyed to the oven probably the most critical equipment in the bakery.

With a tunnel baking oven it is possible to bake full racks of products at one time.

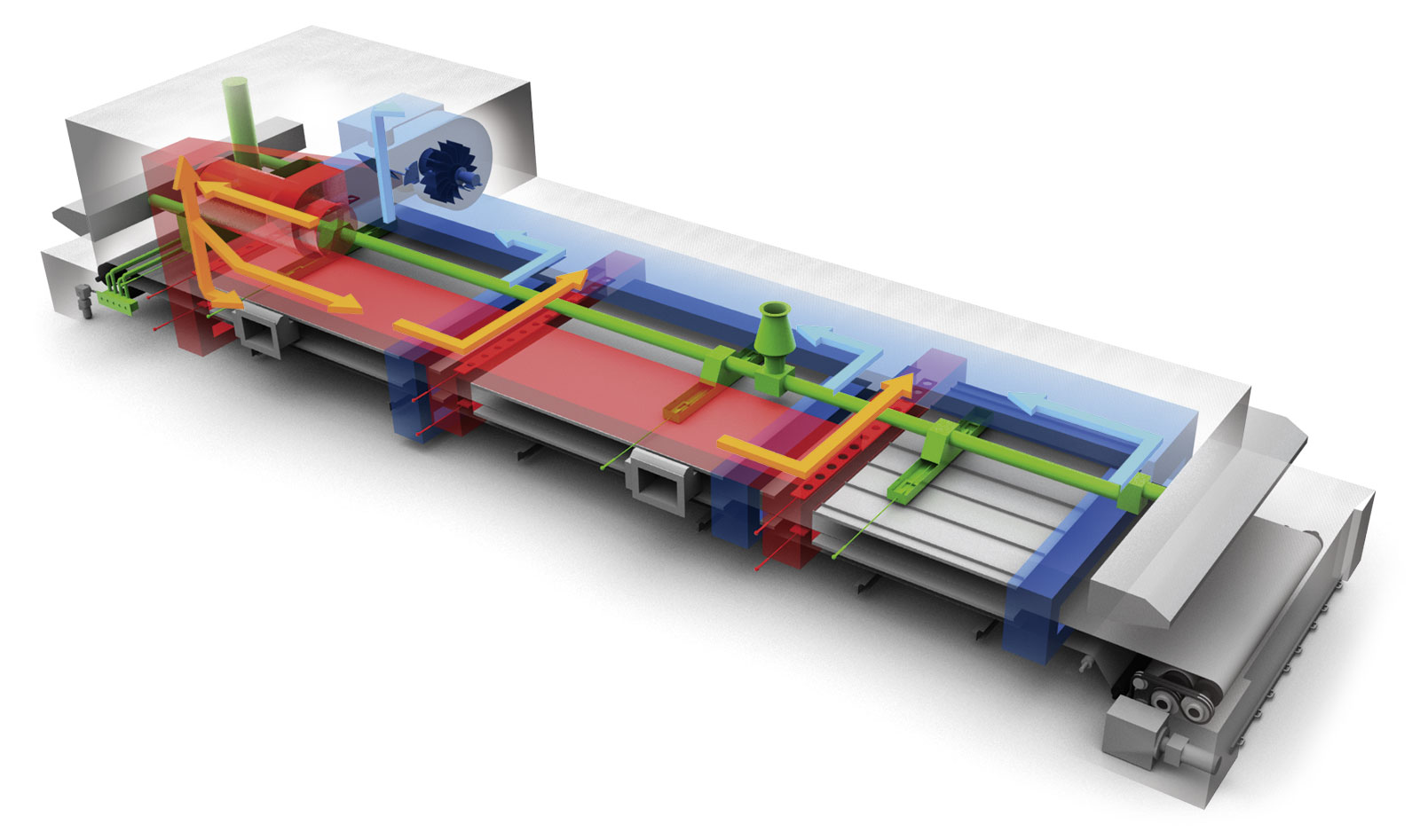

The hybrid tunnel oven baking system is used by combining two or more different heating systems high temperature suitable for products requiring high temperatures 400 c and reduced cooking times 120 sec.

This way you can bake many products at one time.

Therefor we developed a tunnel oven with tray stacking.

Meats are usually cooked on long skewers that are either inserted directly into the oven or cooked over the mouth of the oven.

Tunnel ovens use different conveyor speeds to allow different cooking or baking times.

One of the biggest advantages of these ovens is that once they are heated they will maintain a consistent high temperature for hours with very little additional fuel.

With this oven you can stack multiple trays and bake large quantities of products at the same time.