206 slow hardener is used when extended working and cure time is needed or to provide adequate working time at higher temperatures.

West system epoxy slow hardener cure time.

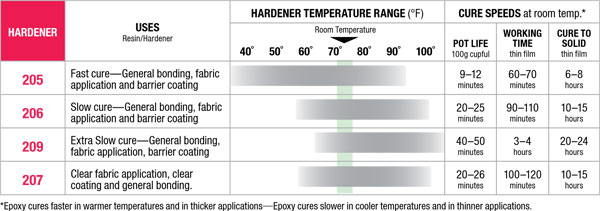

Each west system epoxy hardener has an ideal temperature cure range.

At any given temperature a mix of each of these hardeners with 105 resin will go through the same cure stages but at different rates.

Cure to a solid state at 72 f 22 c.

6 to 8 hours.

At any given temperature each epoxy resin hardener combination will go through the same cure stages but at different rates of speed.

Cured resin and hardener yields a rigid high strength moisture resistant solid with excellent bonding and coating properties.

60 f 16 c 206 a slow hardener 0 44 pt.

Epoxy cures slower in cooler temperatures and in thinner applications.

Ensure you have enough working time.

206 slow hardener is used when extended working and cure time is needed or to provide adequate working time at higher temperatures.

10 to 15 hours.

Pot life at 95 f 35 c.

1 to 4 days.

206 b slow hardener 0 86 qt.

Hardener cure speed and epoxy temperature.

Pot life at 72 f 22 c.

20 to 25 minutes.

Cure to a solid state at 95 f 35 c.

Each epoxy hardener has an ideal temperature cure range.

70 f 21 c 209 sa extra slow hardener 0 66 pt.

Cure to maximum strength at 72 f.

Each has a different cure time and an ideal temperature cure range.

There are four west system hardeners.

Cure time dictates how long you must wait before removing clamps or before you can sand or go on to the next step in the project.

20 to 24 hours.

15 to 20 minutes.

206 c slow hardener 0 94 gal.

Cure to maximum strength.

Not intended for clear coating.

4 to 9 days.

Cure to a solid state.

Two factors determine an epoxy mixture s open time and overall cure time.

Cured resin and hardener yields a rigid high strength moisture resistant solid with excellent bonding and coating properties.

As a general rule double the cure time for every 18 f drop in temperature.